MIL-DTL-48556B

3. REQUIREMENTS

3.1 First article. When specified (see 6.2), a sample shall be subjected to first

article inspection in accordance with 4.2.

3.2 Conformance. A sample shall be subject to conformance inspection in

accordance with 4.3.

3.3 Quadrant. The quadrant shall conform to drawing 13005102.

3.4 Environmental.

3.4.1 Storage temperature. The quadrant shall be thermally stabilized at

temperatures of +160 ± 5°F and -60 ± 5°F for a period of not less than 4 hours at each

temperature. While thermally stabilized at these temperatures, the quadrant shall be

inspected and shall not exhibit any signs of physical failure or damage. Upon return to and

stabilization at standard ambient temperature, +60°F to +90°F, the quadrant shall meet the

requirements of 3.5 through 3.14 inclusive.

3.4.2 Operating temperature. The quadrant shall meet the requirements of 3.8

through 3.14 inclusive while exposed to and thermally stabilized at temperatures of +145 ±

5°F and -50 ± 5°F for a period of not less than 4 hours at each temperature. Upon return to

and stabilization at standard ambient temperature, +60°F to +90°F, the quadrant shall meet

the requirements of 3.5 through 3.14 inclusive.

3.4.3 Shock. The quadrant shall withstand a total of 75 shock impulses along 3

mutually perpendicular axes as defined in Figure 1. Each shock impulse shall be a half

sine wave with a time duration of .010 ± .001 seconds and peak amplitude for each shock

impulse as shown in Table I. Subsequent to shock, the quadrant shall show no evidence of

damage or physical failure and shall meet the requirements of 3.5 through 3.14 inclusive.

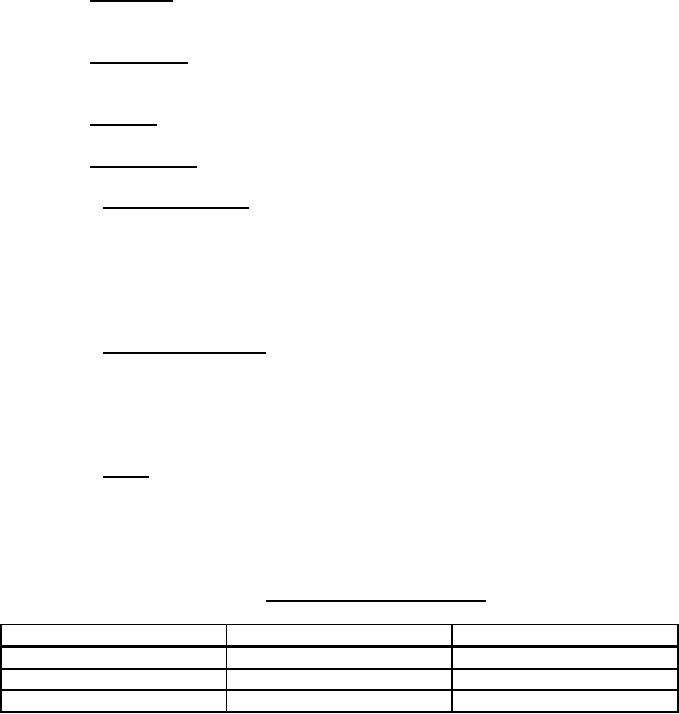

TABLE I. Shock orientation and impulse.

Orientation

Shock impulse and direction

Number of impulses

Longitudinal

-90 g's, +90 g's

15 each direction

Vertical

-80 g's, +80 g's

15 each direction

Transverse

-80 g's

15 total

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business